Collection:

-

- All Navigation

-

-

- Coffee Machines Navigation

-

-

- Professional Coffee Machines Navigation

-

- Automatic Coffee Machine

- Single Group Espresso Machine

- 3 Group Espresso Machines

- 2 Group Espresso Machines

- Turkish Coffee Machines

- Coffee Machine Equipment

- De'longhi Coffee Machine

- Turkish Coffee Machines

-

- Home Appliances Navigation

-

- Refrigerators

- Washing Machines

- Cooker

- Ovens

-

- Kitchen Appliances Navigation

-

- Microwaves

- Coffee & Spices Grinder

-

- Water Heater Navigation

-

- Solar Water Heater

- Electric Water Heater

- Under Sink Water Heater Drivers

-

- All Spare & Accessories Navigation

-

-

- Commercial laundry Spare Parts Navigation

-

- Drain Pump for Washing Machine

- Laundry Accessories

- Laundry Motors

- Laundry Sensor

- Washer Contactor

- Solenoid Valve

- Washing Machine Brackets

- Washing Machine Circuit Board

- Washing Machine Control Unit

- Washing Machine Spare Parts

-

- Refrigerator Spare Parts Navigation

-

- Air Dampers

- Compressors

- Compressor Overload Protector

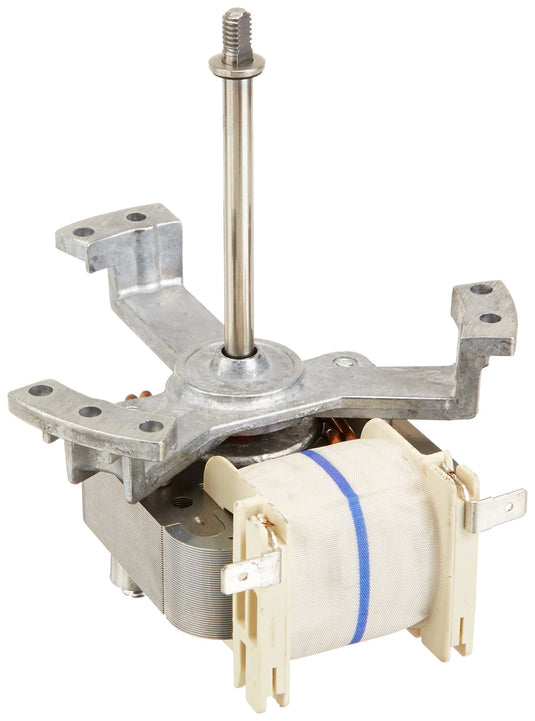

- Convection Motor

- Condensing Coils

- Cooling Defrost Thermistors

- Oven Spare Parts

- Automation Spare Parts

- Cooker Spare Parts

- Dishwasher Spare Parts

- Ice Machine Spare Parts

- Commercial Kitchen Equipment Spare Parts

- Tumble Dryer Spare Parts

- Vacuum Cleaner Spare Parts

- Coffee Machine Spare Parts

-

- Energy & Power Analyzer Navigation

-

- Power Quality Analyzer

- Analog Output Modules

- Programmable Compact Controller

- Electrical and Electronics

-

- Stabilizer and Transformer Navigation

-

- Three-phase voltage Stabilizer

- Relay Voltage Stabilizer

- Variac transformer

- Voltage Transformer

- Dehumidifier

-

- Laundry Equipment Navigation

-

- Commercial Washing Machine

- Commercial Dryer

-

- Air Conditioners Navigation

-

- Central AC

- Split AC

- Window AC

- Portable AC

- Kitchen Equipment

- Home

- Coffee Machines

- Home Appliances

- Air Conditioners

- All Spare Parts

- Best Seller

- Services